Forward-moving unmanned forklift LXR15-A

LXR15-A is a front-moving unmanned forklift that uses multi-line laser radar 3D SLAM natural navigation technology. It has a load capacity of 1.5 tons and a lifting height of 3 meters, featuring flexible operation and high lifting advantages, making it suitable for picking and placing goods on high shelves, which helps improve warehouse space utilization. It can be applied in scenarios such as warehouse access, vertical storage access, production line transportation, material cage stacking, and drive-in warehouse operations. It supports switching between automatic and manual modes.

Function:

Key words:

Yuanqiu New Energy

| Vehicle dimensions (L*W*H) | 2440*1020*2310mm | Voltage and capacity | 24V/210Ah |

| Load capacity | 1.5T | Maximum speed (loaded/unloaded) | 5.5/6.0 km/h |

| Lifting | 3300mm | Walking accuracy error | ±20 mm |

| Turning radius | 1840mm | Stopping accuracy error | ±10 mm |

| Fork dimensions (L*W*H) | 1070*100*40mm | Maximum climbing ability (loaded/unloaded) | 6%/10% |

| Charging method | Manual/automatic recharge | Navigation method | 3D SLAM natural navigation |

| Charging duration | <2h | Communication method | Wireless LAN/supports 5G |

| Continuous working duration | 5-8h | Walking function | Forward/Backward/Turning |

| Luxury configuration |

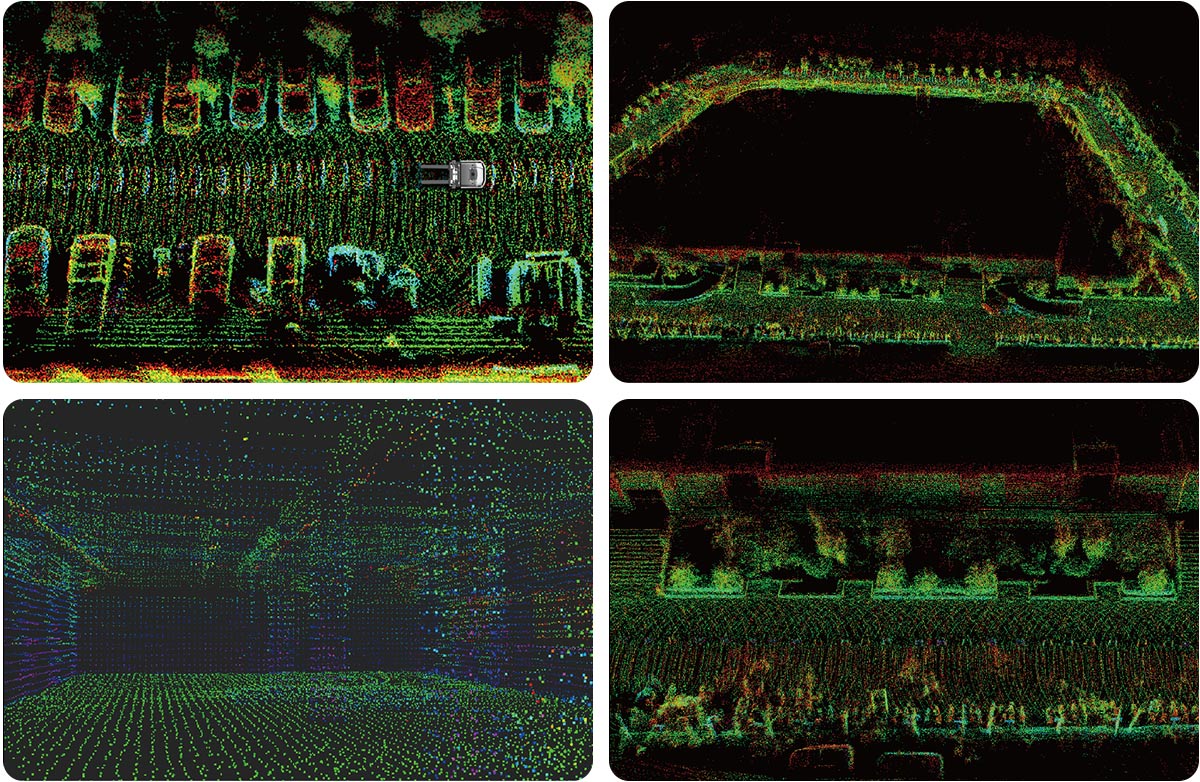

3D positioning navigation |

3D stereoscopic protection |

|

The entire series of intelligent unmanned forklifts is equipped with up to 7 high-precision laser radars. |

Using laser radar 3D SLAM technology to construct high-precision 3D scene maps, achieving stable and reliable centimeter-level navigation positioning. |

Omnidirectional surround stereoscopic perception capability, providing 360° 3D safety protection to ensure operational safety. |

| Strong environmental adaptability |

Easy deployment |

Autonomous and controllable |

| Suitable for various complex indoor and outdoor scenarios, achieving all-weather, all-scenario fault-free operation. | No modifications are needed for the operating environment, allowing for quick production use. | Laser radar, core algorithms, and supporting management software are all independently developed and controllable. |

Using multi-line laser radar as the core sensor for 3D scanning, the environmental information is rich, and there is no need to modify the on-site environment and existing business processes, achieving high-precision 3D scene map construction, matching positioning, path planning, and other functions. The matching positioning is stable and adapts to scenes with high dynamic change rates, suitable for various indoor and outdoor environments.

| Accurate and stable Real-time mapping of 3D point clouds |

Environment Strong adaptability |

Easy deployment Quick to put into use |

Low investment cost |

| Can construct 3D point cloud maps of over a million square meters, with rich environmental information features. | Suitable for various indoor and outdoor environments, unaffected by indoor and outdoor lighting interference. | No need to deploy auxiliary facilities in the environment; deployment can be completed in 1-2 weeks with more than 10 unmanned forklifts. | Achieve automation, save labor costs, and improve user profit margins. |

The top, middle, bottom of the vehicle body and the fork tips are equipped with laser radars, which provide obstacle warning and avoidance perception for low, medium, and high positions around the entire vehicle from top to bottom, forming a 360° blind spot-free safety protection for the vehicle body, effectively warning and avoiding various sudden risks.

The 3D SLAM unmanned forklift series uses the Laser Technology 128-line high-precision hybrid solid-state LiDAR to accurately identify pallets, achieving millimeter-level precision. It is suitable for various indoor and outdoor scenarios, capable of accurately identifying pallets day and night, ensuring fault-free operation around the clock in all environments.

Functional Features

Point Cloud Recognition:Independently developed deep learning laser point cloud recognition technology, automatically identifying pallet locations.

Offset Tolerance:Allows manual placement of pallets with a lateral offset of 10cm, a forward and backward offset of 10cm, and an angular offset error range of 10°.

Accurate Calibration:Effectively avoids cumulative errors in pallet position at pickup points associated with traditional technologies.

Raytheon Intelligent 3D SLAM unmanned forklift is equipped with a leading 128-line hybrid solid-state LiDAR, specifically designed to identify various types and sizes of material cages. Through fine feature extraction and pose calculation, combined with high-precision 3D SLAM positioning technology, the unmanned forklift can autonomously navigate to the target location and accurately complete the stacking task of material cages, which not only improves operational efficiency but also ensures the safety and stability of the entire operation process.

Functional Features

Multi-layer high-level stacking, accurate and stable:Raytheon Intelligent 3D SLAM unmanned forklift has accurate perception and positioning capabilities, supporting stacking of up to 4 layers of material cages, ensuring the accuracy and stability of the stacking.

Applicable to indoor and outdoor scenarios, all-weather operation:Equipped with a 128-line high-precision 3D LiDAR solution, suitable for various indoor and outdoor scenarios, capable of stable and efficient operation both day and night.

Ultra-high local control accuracy:Stacking accuracy is extremely high, with error control within 5mm, ensuring the accuracy of each stacking.

Intelligent AI anomaly detection, safe and efficient:Using intelligent AI anomaly detection algorithms, the system monitors the position and angle of the forklift and material cages in real-time and makes fine adjustments. If unstable stacking is detected, the system will immediately trigger a safety mechanism, guiding the forklift to recalibrate without needing to exit, ensuring operational safety with high efficiency.

Application Scenarios

Flying wing vehicle unmanned loading and unloading

Cross-floor transportation

Multi-layer material cage stacking

Docking drive-in shelves

Multi-vehicle collaboration

Connecting the roller conveyor

Docking with the warehouse

High-level access

Docking the stacking machine

Connecting with unmanned logistics vehicles

Factory area vehicle-road collaboration

Outdoor work

Application Industry

Automotive electronics industry

Battery swapping industry

Cold chain industry

Leather manufacturing

Sugar industry

Electronic components industry

Electrical machinery manufacturing industry

3C electronics industry

Papermaking industry

Daily chemical industry

Electrical appliance manufacturing industry

Electronics industry

Online consultation

Message

If you are interested in our products and want to know more details, please leave a message here and we will reply to you as soon as possible.